Skip navigation

-

(315) 234-4347 Call us now

-

My account Login / Create Account

-

0

CHECKOUT $0.00

Shopping Cart

You have no items in your shopping cart.

La-Co

Recently viewed products

La-Co

Leak Detectors & Penetrants

La-Co 1-Pt. Sure-Chek All-Temperature Leak Detect Part# - 32850

1 EA

$19.68

Chemicals Lubricants & Paints Other

La-Co Pipetite Paste Pipe Thread Sealant 1/4 Pt Gray Part# - 12109

1 EA

$11.56

Sealing Products

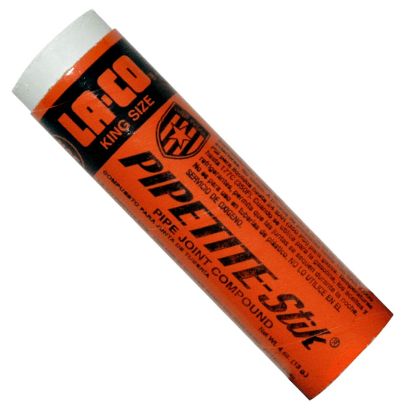

La-Co Pipetite Stik Thread Compound 4 Oz Part# - 11176

1 DOZ (12 EA = 1 DOZ)

$64.40

Markers

La-Co Quik Shot Markers 12Oz Spray Can Inverted Orange Part# - 61114

1 CA (12 EA = 1 CA)

$92.40

- 1

- 2